Machinery and

Production

From Cooking Chocolate to Eating Chocolate

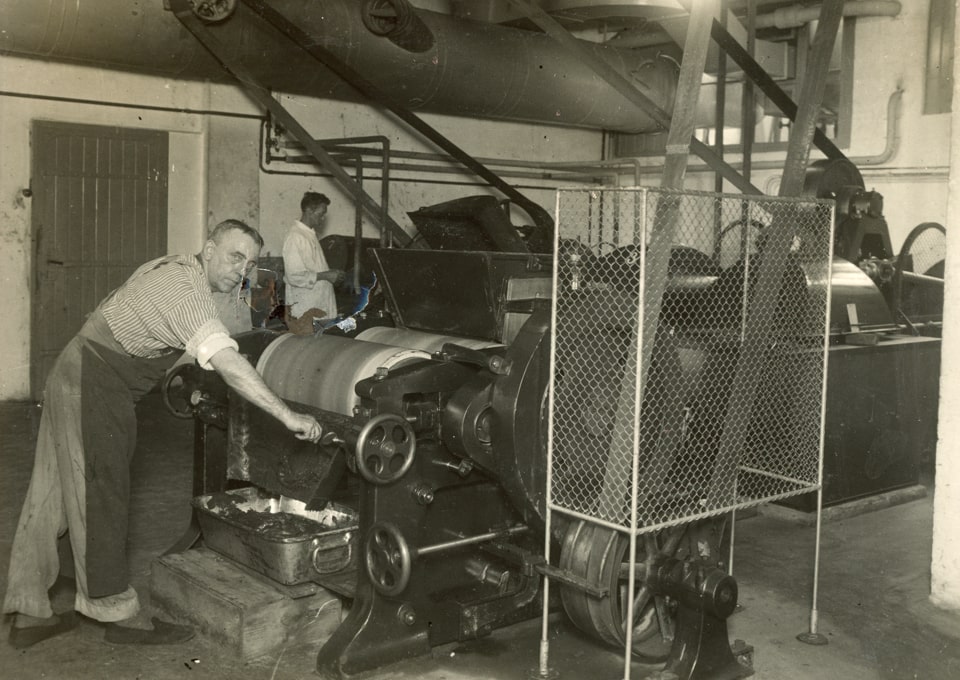

From Manual Labour...

... to Modern Production

The Pretzel Twister

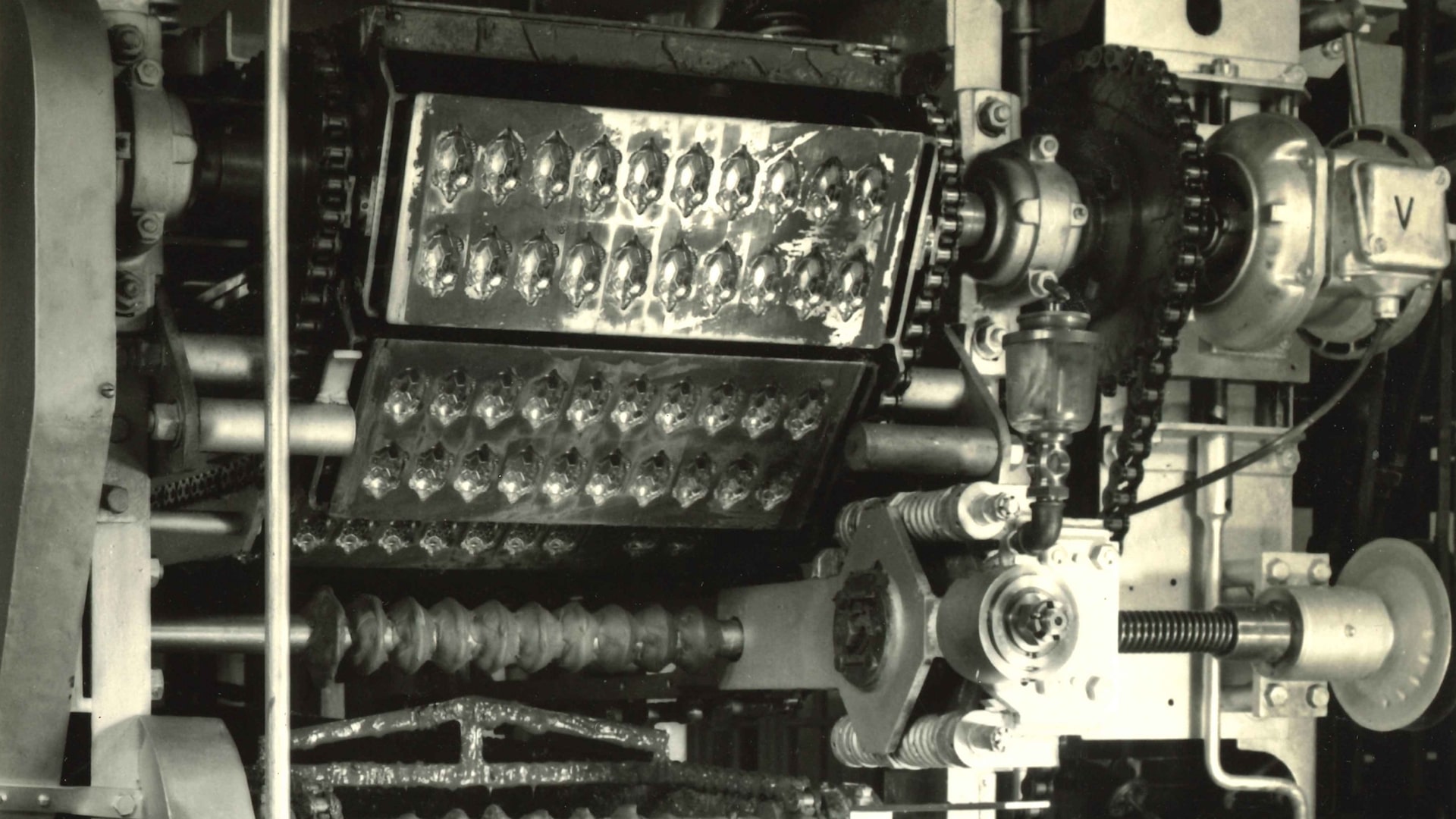

Production Lines for Future Products

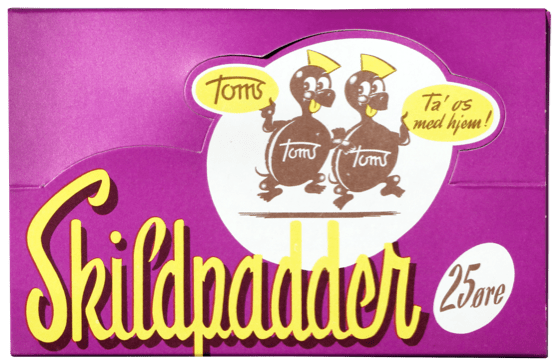

From flat to tall turtles

The first ’Skildpadder’ from 1948 were flat and filled with rum cream. In 1967, caramel was also added to the ’Skildpadder’, and they became taller to accommodate both types of filling.

Three Factories for the Latest Technology

1926 – Amager

1962 – Ballerup

2019 – Nowa Sol

World famous architecture in Ballerup

During the 1960s and 70s companies moved their production sites outside the city centres to achieve room for machinery and streamlined production. The architect Arne Jacobsen made Toms’ new factory a breakthrough for Danish industrial construction. The white surfaces and strict expression of the production area has since garnered recognition from all over the world.

The transformation from open fields to chocolate factory in Ballerup was remarkable. Arne Jacobsen articulated: “All buildings may be called ‘architecture’ – if they are created properly. I am thinking of – if you are driving out of Copenhagen and seeing the factory building out there… – it’s generally nice.”